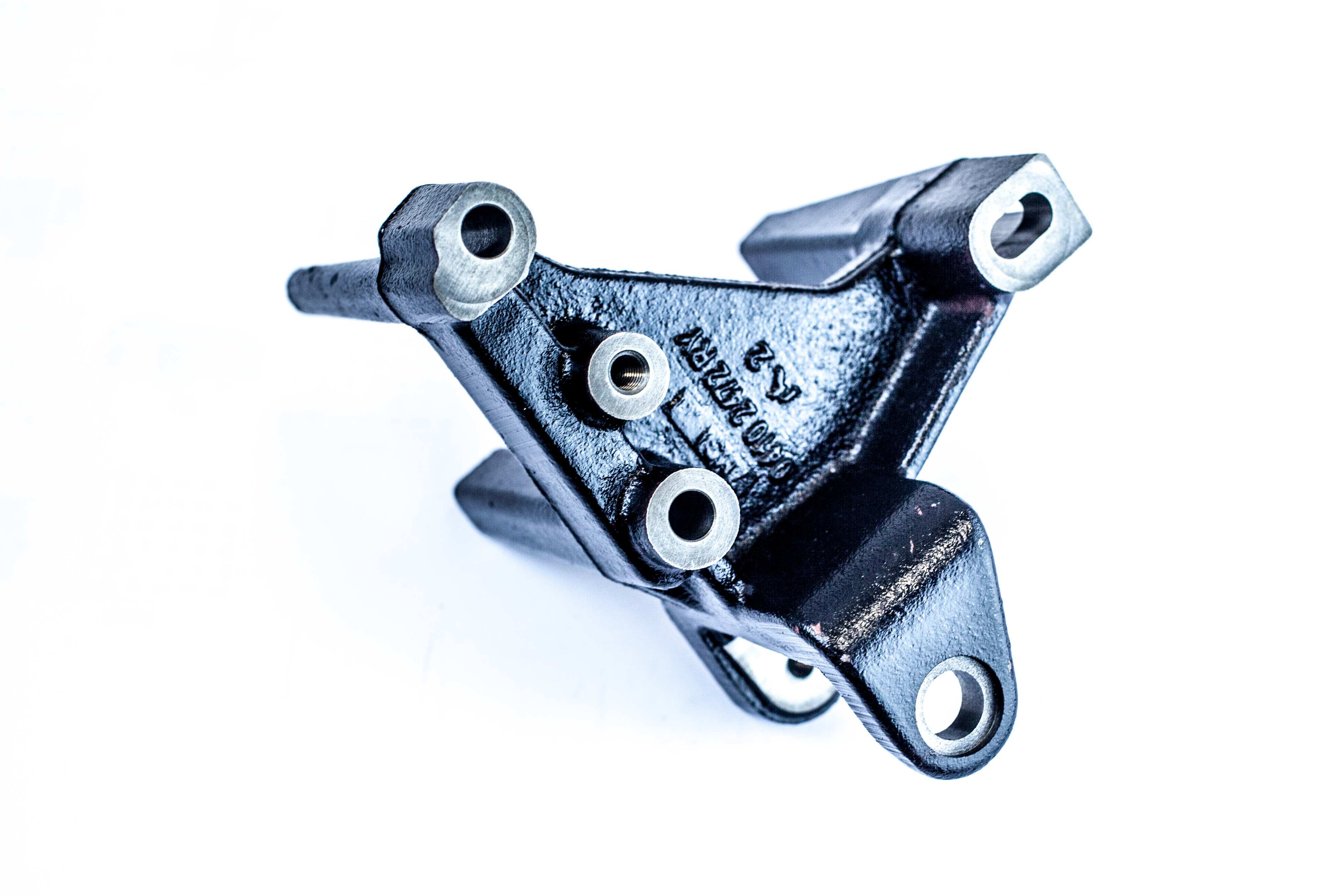

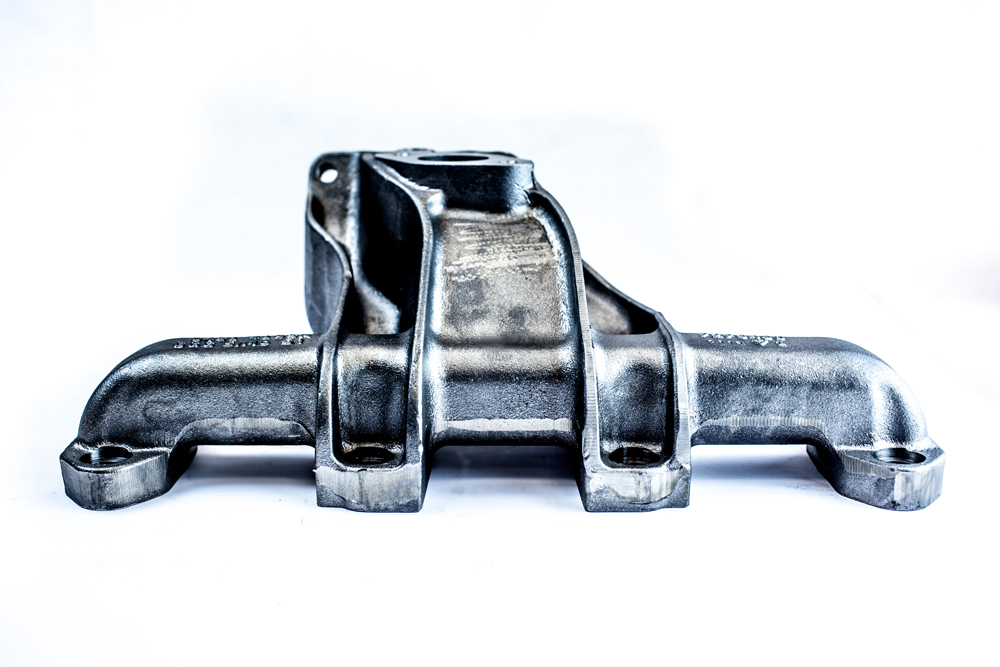

HEAT, CORROSION, VIBRATION, CONFINED SPACES: THE PARTS WE DEVELOP MUST WITHSTAND EXTREME CONDITIONS.

The exhaust manifold is one of the key components in this field. It is a central element in a motor’s performance. Any leakage will result in immediate loss of power, or increase the risk of pollution. With this in mind, we take into account the environment in which the component will be used before industrializing it.

Whether for the agricultural or energy sectors, or for public works machinery, we contribute to a part’s design with the greatest possible care and diligence. Together with the founder, we optimize the part’s shape to facilitate its handling by the machining equipment, which guarantees its quality. This work is made possible by a network of founders who partner with and support SMTG.

750 MM X 750 MM X 750 MM

30 000 CATALYST CARRIERS ASSEMBLED

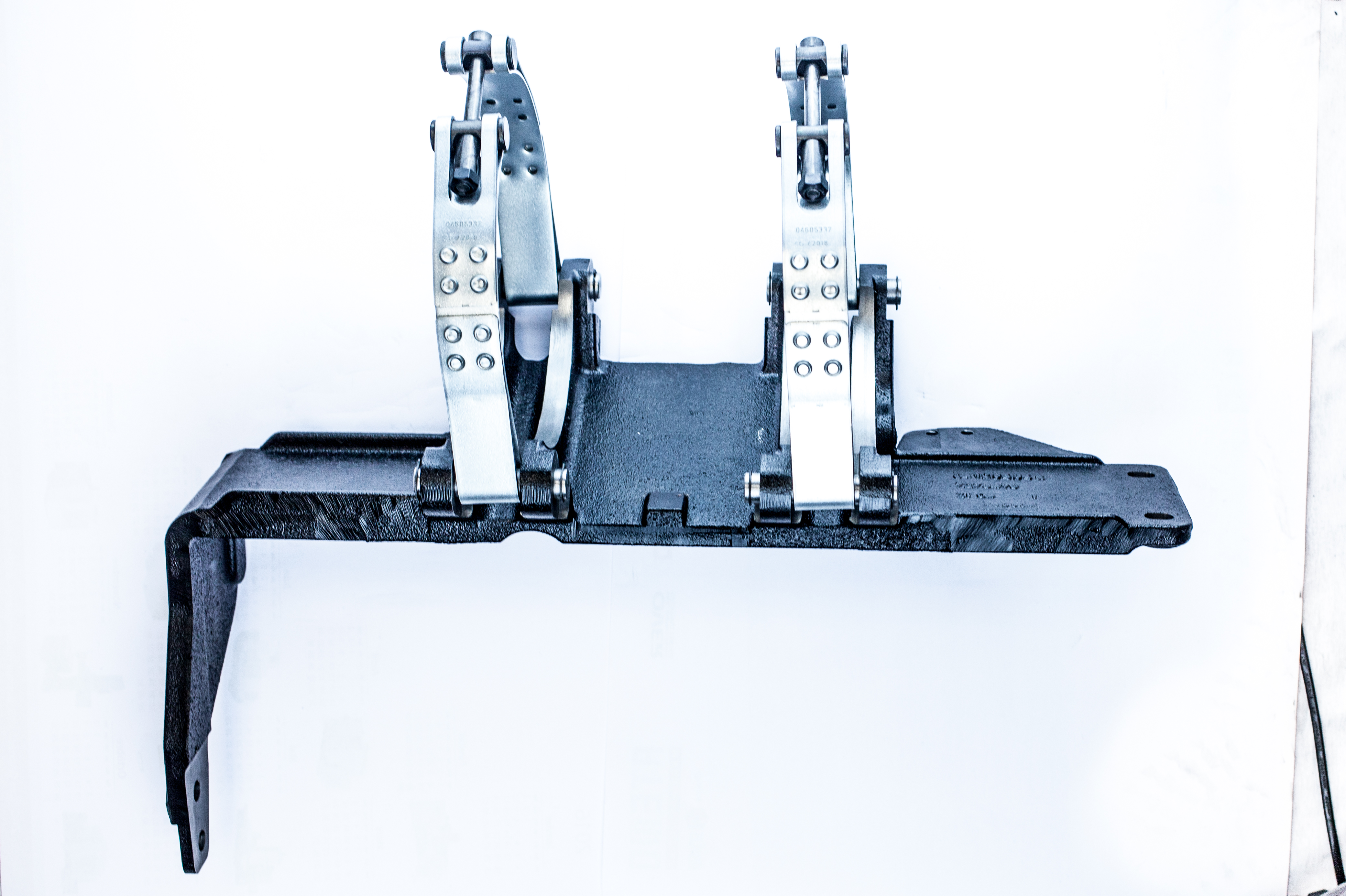

CONTOUR TRACER