MOVEMENT, MECHANICAL FRICTION, INTERACTION BETWEEN COMPONENTS: THE PARTS WE DEVELOP MUST WITHSTAND CONSTANT AND INTENSE STRESS.

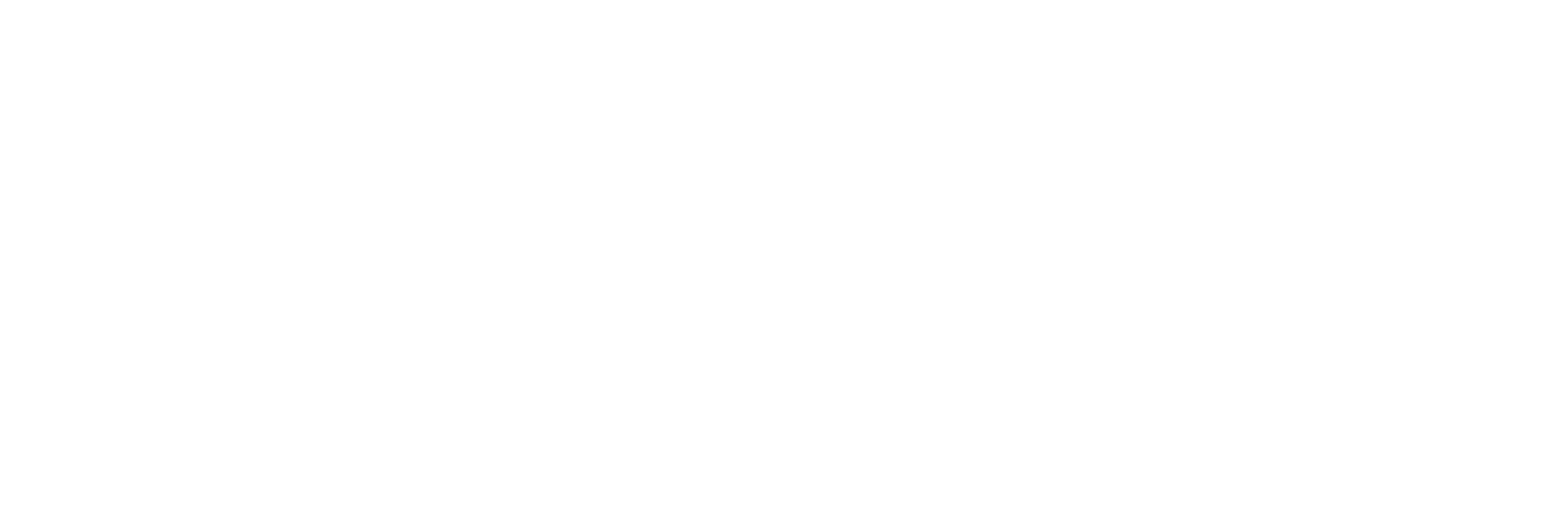

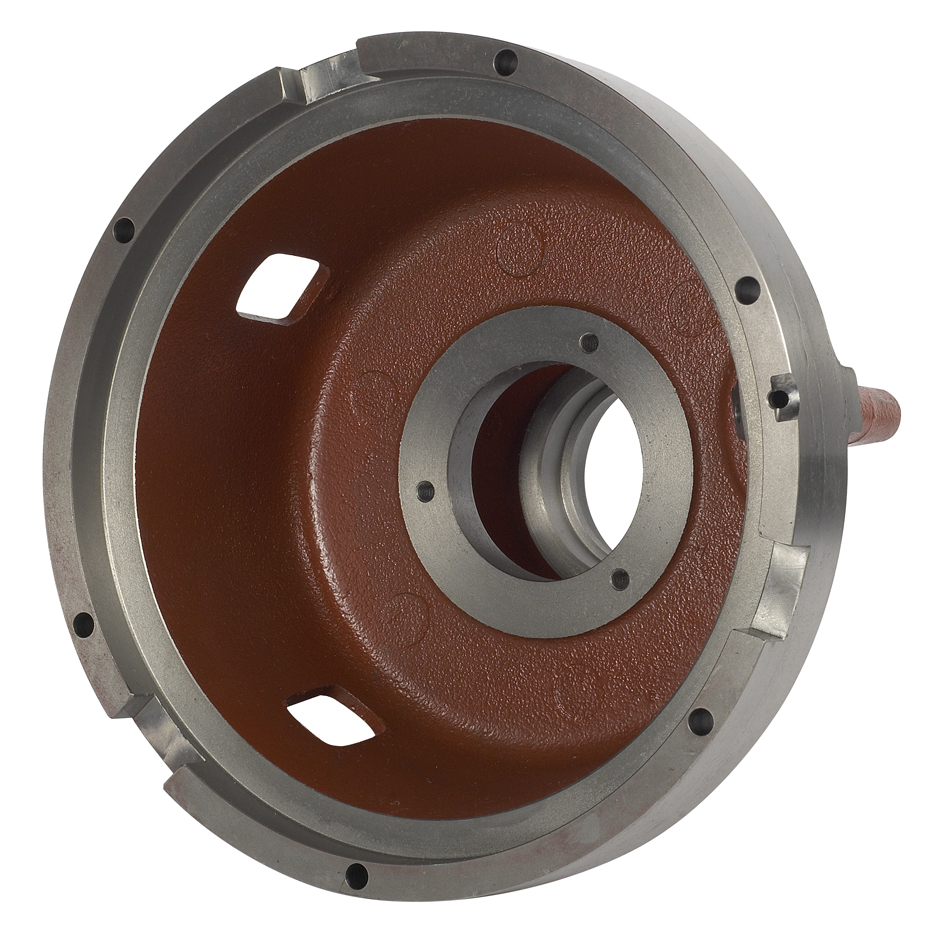

Gearboxes, bearing housings, reducers: the parts developed contribute to the proper coordination of movement within your mechanical assembly. Taking the interaction between the components into account is therefore of utmost importance.

We guarantee the strength and accuracy of our parts so as to ensure your transmission’s smooth and reliable performance.

This is made possible thanks to many skills:

- kinematics.

- control of raw materials and their deformation.

- mastery of surface conditions which allows us to fully understand the effects of friction and wear.

This knowledge allows us to project the parts into their future environment and foresee how they will perform in it.

TO BE ASSEMBLED IN GEARBOXES

750 MM X 750 MM X 750 MM

CENTRELESS OR WITH CENTREHOLE

CONTOUR TRACER